INTERVIEWWith the environment an ever-pressing concern in and out of the fashion industry, brands such as Levi Strauss are continually working to reduce the amount of waste created during the production process. The denim company recently announced its new water strategy, which will take a localized approach to its water conservation, dependent on the needs of each factory’s surrounding area.

Below, FashionUnited spoke with Michael Kobori, the vice president of sustainability at Levi Strauss & Co. to learn more about the brand’s new water strategy.

What has been the process of developing the new water strategy for Levi's, and how will it affect the company's overall waste?

In 2007, we conducted the apparel industry’s first life cycle assessment, which shed light on the industry’s impact on watersheds around the world. This inspired us to join the Better Cotton Initiative in 2010, launch Water We recognize that water issues pose some of the greatest threats to the global economy and people around the world. We also recognize that water demand and scarcity are variable and that we were operating according to a "one size fits all" approach that did not address the reality of water stress. Now that we have applied our Water Less® techniques to two-thirds of our products en route to 80 percent by 2020, scaled the Better Cotton Initiative to two-thirds of our cotton supply en route to 100 percent more sustainable and resource-efficient cotton by 2020, and open-sourced our Screened Chemistry program to the industry, we see an opportunity to take another step forward, to use the science and tools at our disposal to focus our reduction efforts where they are most critical, increase water access and inspire the collective action that is essential to delivering the change that’s needed. Over the past decade, it has become standard best practice for companies to address the amount of water that they use. As water stress intensifies in various regions, however, it is increasingly clear that saving a liter of water where water is plentiful is not as critical as a liter where water is scarce. Therefore, we felt we needed to address our water use in the context of local water stress. While there is no prevailing guidance on setting science-based water targets in a local watershed context, we have access to highly respected, publicly-available tools and datasets, such as the World Resources Institute’s Aqueduct Water Risk Atlas, that help us understand where water stress is greatest. Though we have not established overarching global targets for suppliers in areas of low- and medium- water stress, we intend to continue to build on our progress there as we empower facilities in those categories to pursue their contextual targets. We also recognize that local water stress will evolve, so we plan to update our supplier water stress classification at least once every three years. We will continue to implement and expand programs designed to reduce water use in manufacturing. These include:

· Our water Recycle and Reuse program: over the past year, we have tripled the number of approved R&R facilities and recognized five fabric mills in areas of high-water stress.

· Our partnerships with the International Finance Corporation Partnership for Cleaner Textiles (IFC PaCT) and the Apparel Impact Institute’s Clean by Design program.

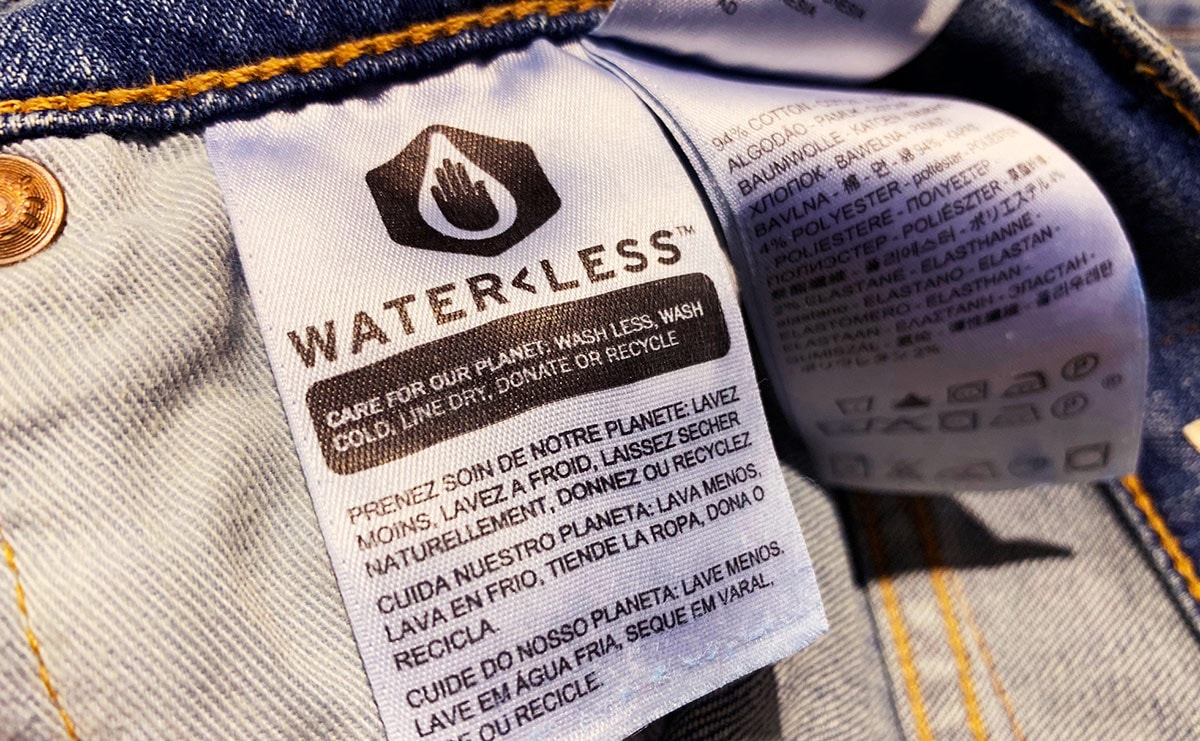

· Our existing Water Less® technologies, which can significantly reduce the amount of water that we use to wash or finish jeans, which saves not only water, but also energy. As we developed this strategy, we consulted various suppliers, each of whom supported the idea of establishing contextual water targets that respond to local water stress. Going forward, our technical experts in the field will continue to work with vendors to drive efficiency, as they have been to date. What’s more, suppliers are already engaged – and deeply invested – in the effort to reduce water use. In water-stressed regions, suppliers have begun to install water-efficient machinery and recycle water because these represent strong and necessary investments for their businesses. We will target the total amount of water our suppliers use to make fabric and garments. This will include water used to manufacture other brands’ products. We cannot limit focus on only the water used on our products if we want to ensure that the environmental conditions around our facilities improve. Ultimately, what’s important is the impact that the apparel supply chain has on the watersheds and communities that support it, not just the amount of water used to make LS&Co. products. We want to help our suppliers become more efficient and resilient and leave more clean, fresh water for local communities and the environment. To our knowledge, we are the first company in the apparel industry to set contextual water

targets for all tier one and two suppliers, and among the first in any industry to do so. Our

original Water Less® targets invoked a one-size-fits-all approach to scale the Water Less®

finishing techniques at an ambitious rate. Our new targets apply a contextual approach to address local watershed needs. This data-driven, outcome-oriented approach will enable a leap in the sustainability and resiliency of our supply chain, and we want to extend that resiliency to the watersheds and communities that support it. Water Less® techniques and the Recycle and Reuse Standard remain key pillars of our new

Water Action Strategy. What will change is that we will move to qualify Water Less® at the facility-level. Fabric or products coming from manufacturing facilities that meet the targets that we issue, which will vary depending on whether they’re located in areas of low, medium or high-water stress, will qualify as Water LS&Co. will help all its key suppliers achieve the Water Less® designation by 2025 utilizing tools and programs such as existing Water “We all know that water is perhaps the most critical resource on the planet and that many places, including countries the apparel industry sources from, are struggling with water crises,” said Liz O’Neill, Executive Vice President and President of LS&Co.’s Global Product, Innovation, and Supply Chain. “This announcement is an illustration of what sustainability means to us now: innovative, responsive, scalable programs that drive impact and inspire collective action to address the most pressing social and environmental issues facing our business, industry, and planet.” In addition, as part of the Water Action Strategy, LS&Co. will continue to reduce the amount of water required for cotton cultivation by collaborating with organizations like the Better Cotton Initiative to implement better farming methods, while simultaneously continuing to explore the use of alternative raw materials such as hemp and regenerated fibers that can reduce the amount of water used in the cultivation phase. LS&Co. will also continue its industry-leading work on chemicals, which includes not only the Zero Discharge of Hazardous Chemicals commitment for 2020, but also its own open-source Screened Chemistry protocols, which prevent hazardous chemicals from entering the apparel supply chain. Water pollution contributes to water stress, so ensuring that the water that gets put back into the environment is clean and safe is as important as addressing water consumption at earlier stages. This comes on the heels of the release of our industry-leading Climate Action Strategy in 2018. Along with rising global average temperatures, climate change is manifesting in altered precipitation patterns, droughts, floods and storms that are increasing in frequency, severity, and duration and impacting companies and communities around the world. While our Water Action Strategy takes essential steps to make our business and the communities it touches more resilient to the water-related impacts of climate change, taking swift action to mitigate climate change is central to our sustainability approach. Images: Courtesy of Levi Strauss & Co.Your company is taking a localized approach to water conservation. What went behind the decision to do this?

What are the methods Levi's is taking in its production process in order to meet the proposed commitments by 2025?

Will Levi's be making changes to its production houses — in terms of machinery, labor, etc. — throughout this process? How so?

Can you explain more about the Water Less program?

How does the new water strategy align with Levi's greater approach to sustainability?

* This article was originally published here

No comments:

Post a Comment